3D Printing Innovations in Dentistry

Harnessing the capabilities of technology, IMR volunteers in Ecuador used 3D printers to craft personalized 3D-printed partials for patients, elevating smiles and multiplying the positive effect dental care has on IMR patients. This initiative goes beyond dental innovation; it’s a testament to what can be achieved when diverse skills converge for a shared purpose.

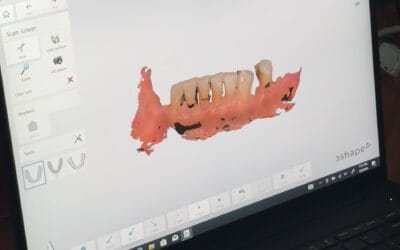

The precision and accuracy achieved through 3D printing are unparalleled in limited-resource settings. Traditional methods of creating partials and dentures often involve multiple steps, including manual mold-making and adjustments, which can lead to patient inconsistencies and discomfort. However, 3D printing allows for creating highly customized, patient-specific dental prosthetics with remarkable precision. This results in a comfortable fit and natural appearance that greatly enhances the patient’s quality of life.

One of the most significant advantages of 3D printing is the speed at which prosthetics are produced. IMR patients came in and left the same day with beautiful, high-quality partials. Traditional manufacturing processes in the U.S. can be time-consuming. But with 3D printing, the entire process is expedited, allowing patients to receive their partials or dentures in a fraction of the time it would take using conventional methods.

3D printing also offers a level of versatility in field-based dental care that was previously unimaginable. Dental professionals can easily adjust and refine the design before printing, ensuring that the final product meets the patient’s specific requirements.

Want to be a part of bringing innovation to communities with little to no access to medical or dental care? Join IMR on an upcoming trip!

Join Us in Making a Difference.

Bring much-needed acute medical and dental care to a beautiful, culture-rich destination. You can join an IMR medical mission team today!